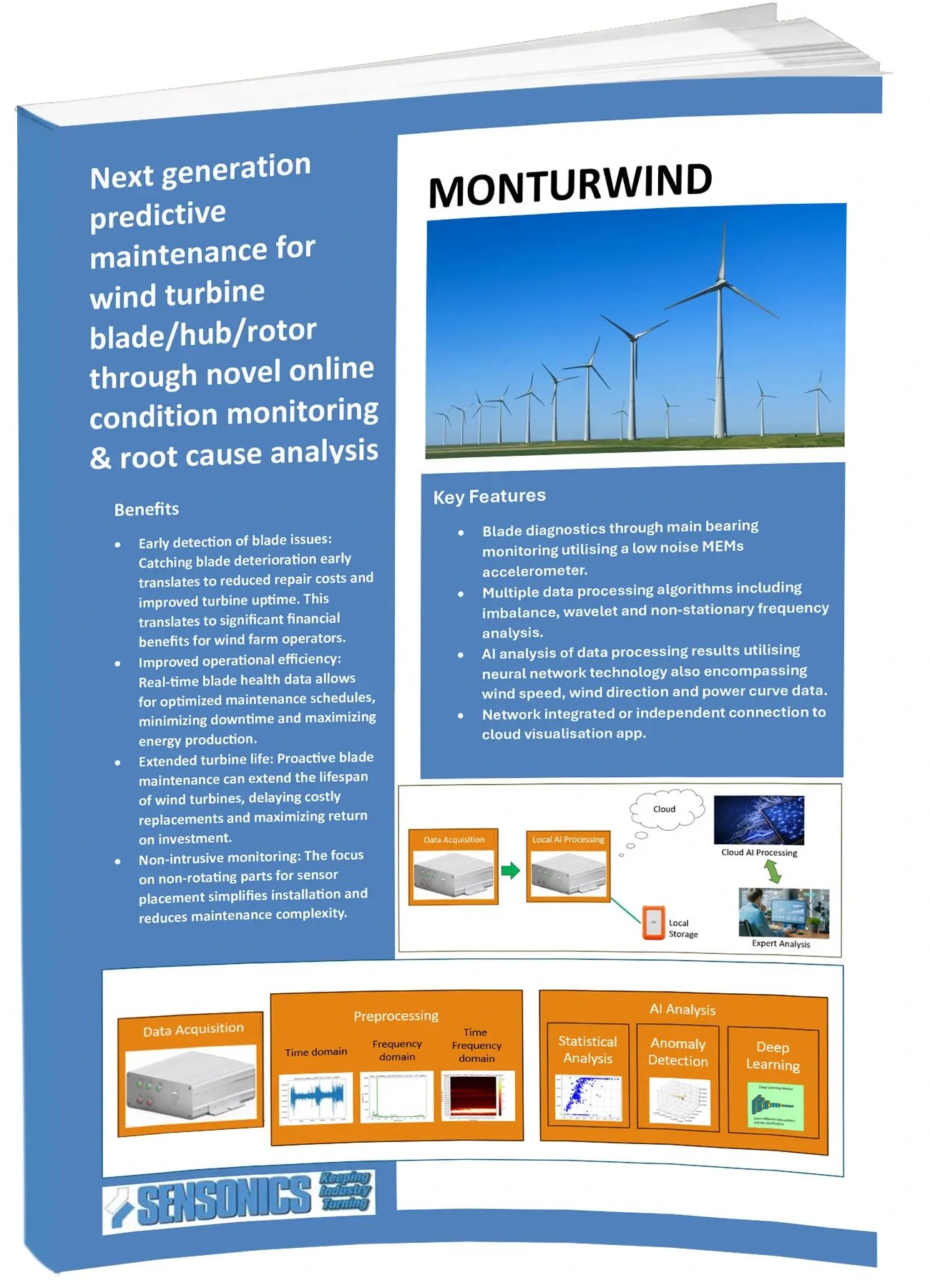

MONTURWIND

A collaborative team from Natural Power (part of the Fred Olsen Group), the University of Huddersfield and Sensonics, are working on a UK government funded project for wind turbine blade health monitoring that holds immense promise for the wind energy industry. By leveraging sensor technology, university expertise, and real-world data collection, this project has the potential to revolutionise how we maintain wind turbines. Fill in the form below to download further information about the project.

Wind Turbine Blade Condition Monitoring

Wind turbine blades can experience a variety of damage, including:

- Cracks: Can appear in the blade body and propagate rapidly, potentially collapsing the entire structure

- Delamination: Reduces the blade's stiffness

- Debonding: Can occur between the skin and adhesive, or between adhesive joints

- Leading edge erosion: Caused by the continuous impact of small atmospheric particles, such as rain droplets, hail, and salt

- Icing: Can occur in extremely cold weather

- Fibre breakage: Can occur in the structural elements of the blade

- Interlayer peeling: Can occur in the blade

Simply fill in the provided form for your FREE copy!