Rotating Machine Protection

capabilities

Rotating Machine Protection

Sensonics can provide a full turn key project service for rotating machinery protection complimented by a range of innovative products. This is our core business and we have been providing vibration, position and speed monitoring and protection systems to industry worldwide since the 1970’s.

Our experience is embedded in our range of equipment where over the years we have developed specific measurement algorithms focused on various industry sector needs such as power, oil & gas, metals, etc. this experience and knowledge is now operating on our third generation hardware platform Sentry G3, the most advanced machinery protection system available on the market.

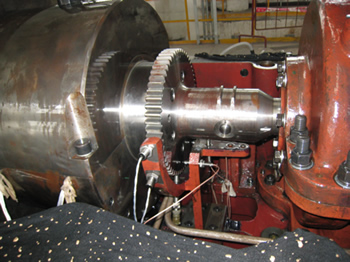

Vibration Monitoring

Sensonics are experts in the sensing of vibration and can recommend appropriate methods and instrumentation for rotating machinery from small pumps through to large power turbines. As a sensor designer and manufacturer we have a thorough knowledge of the sensing technique and any limitations in terms of application.

Our depth of experience covers both piezoelectric, magnet / moving coil and proximity type devices with designs suitable for general industrial applications along with specialisation in high temperature, extreme pressure and radiation resistance.

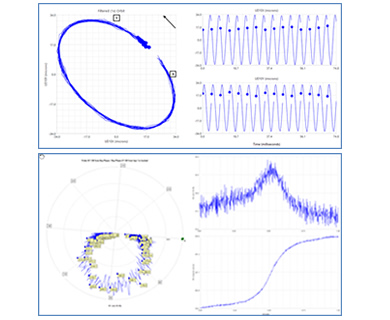

Our signal processing equipment utilises software algorithms that have been developed for specific vibration monitoring applications, we can provide measurements according to ISO standards for general machinery protection, through to synchronous and non-synchronous harmonic analysis.

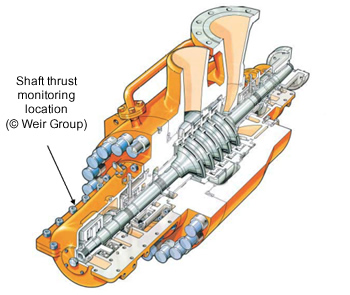

Shaft Position

The position of the machine shaft or wear of the thrust bearing pads are critical measurements on rotating machines where rotors are employed in steam, gas or fluid handling. The challenge is to provide a repeatable measurement utilising a proximity probe in a restricted space with an accuracy of better than 10um.

Sensonics strength is in designing and supplying the right probe with enough measurement range to allow for shaft float and to avoid unwanted side target interference. Along with sensor mounting arrangements that provide mechanical adjustment in conjunction with signal processing and calibration facilities we can offer the complete package.

We have a range of solutions from 4-20mA loop powered devices through to 2oo3 voted channel arrangements.

Overspeed Protection

Overspeed protection is a key requirement for critical rotating plant where failure of the speed governing system can lead to damaging consequences.

Independent electronic speed monitoring and shutdown is essential to reduce this risk to an acceptable level and is a standard upgrade for mechanical systems that require a physical overspeed test to demonstrate compliance. Sensonics have been providing high integrity overspeed protection systems for many years with proven field reliability. The architecture of our system and facilities offered has been developed in conjunction with our customers, offering up to a SIL-3 integrity level in combination with a range of innovative proof test facilities.

have questions?

Make An Enquiry

Our experienced Application Engineers are available to assist you in solving any problems that you may have concerning the choice and application of any of the Sensonics products in the measurement and control of vibration, position, temperature and proximity.

Make an enquiry today!

Get your copy