Oil & Gas

Our Industries Expertise | Sensonics

Oil & Gas

Sensonics has worked with the Oil and Gas industry since the 1980s providing specialised instrumentation solutions for the condition monitoring of both onshore and offshore critical rotating plants. Our sensors and systems are designed for harsh conditions and can be found monitoring bearing vibration, shaft vibration & position, thrust wear and rotational speed on a wide range of turbines, pumps and compressors. Sensonics also provides seismic detection systems that can be used to help protect liquefied natural gas (LNG) Terminals in the event of earthquakes or other seismic activity.

Our reputation for providing specialist sensing solutions, in supporting leading-edge developments in this field is second to none. Now operating on our third generation hardware platform Sentry G3, the most advanced machinery protection system available on the market.

Power Plant

Sensonics instrumentation offers both monitoring of the dynamic behaviour of rotating machines as well as providing the essential measurement interlocks for the smooth operation of the power plant. Our range of vibration sensors offers both piezoelectric and electrodynamic velocity sensing options for the measurement of bearing and casing vibration with operation up to 450°C. The Senturion X range of proximity probes comply with the API 670 standard and are available with direct 4-20mA processed outputs for vibration, shaft position and speed monitoring. To provide the sensor signal conditioning our Sentry G3 supervisory system has tailored measurement algorithms for both steam and gas turbine applications.

Condition monitoring is available through our optional CMS plugin providing a suite of analysis tools to monitor the detailed dynamic behaviour of the turbine set.

Compressors, Blowers & Pumps

Sensonics offer a wide range of instrumentation to suit compressor, blower and pump machinery utilised in Oil and Gas applications. Our sensors are approved to both ATEX and IECEx standards offering the highest levels of protection and with API 670 standard compliance across the product range our measurements also meet with ISO vibration standards.

Vibration sensor options include piezoelectric accelerometers, velocity sensors and proximity probes. Available with direct 4-20mA processed outputs for vibration, shaft position and speed; a very cost-effective method for less critical plant monitoring.

To provide additional functionality such as shutdown protection (large multistage compressors) and digital communications our Sentry G3 supervisory system, or our DN26G3 monitor which is ideal for local machine panel integration, is both cost-effective solutions.

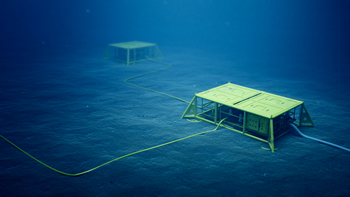

Platform / LNG Terminal Monitoring

Structural vibration monitoring of extraction platforms and LNG plant is an essential protection requirement in the event of a significant earthquake.

Sensonics SA-3 series of seismic switches can play an important role in providing a safe shutdown of critical processes to minimise the impact of such an event.

Hazardous area approved and with optional compliance to ASCE 25-97 for automatic gas shut off valves the SA-3 series can provide an actuating sensitivity between 0.005g to 0.5g.

Specialist Sensing

Oil and Gas exploration is carried out in some of the most demanding environments and Sensonics has worked closely with the industry over the years to develop competence in providing vibration sensing solutions for such applications.

Offering the complete design service in accelerometer and proximity probe vibration sensors we have a range of standard designs suitable for operation in 350 bar pressure environments.

Contact Sensonics for further details.

Our Products

Download the engineers’ guide to specifying vibration monitoring systems

If you are designing a system which uses vibration monitoring then this guide can help you specify vibration monitoring systems.

This guide covers:

- Types of vibration sensors

- Monitoring equipment

- Questions to ask when designing or specifying a vibration monitoring system

- Why work with Sensonics

Please enter your details in the form to get your copy.

Get your copy