Vibration & Position Monitoring Equipment

Industrial Monitoring Solutions

Vibration & Position Monitoring

Sensonics vibration and position monitoring systems offer a range of both contact and non-contact techniques for accurate measurement of absolute vibration, relative vibration and shaft / thrust position on critical machines and infrastructure.

• Global suppliersQuick Enquiry

Sentry G3 Universal Monitoring & Protection System

The Sensonics Sentry G3 concept builds upon the established range of Sentry products and has been designed to be the most flexible and feature-rich machinery protection system available. Each of the G3 module’s four channels can be independently programmed to provide continuous monitoring and protection across a broad spectrum of measurement regimes, including vibration, position, temperature and speed.

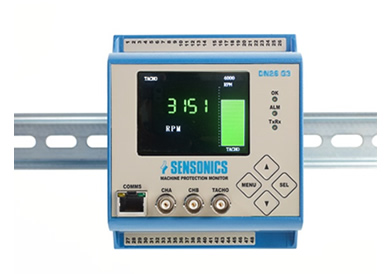

DN26 G3 Intelligent Machinery Protection Monitor

The DN26 G3 Machine Protection Monitor is a high performance fully programmable signal conditioning unit capable of monitoring 2 channels of absolute vibration, shaft vibration or shaft position. An additional third channel is available as a standard for measuring speed or for use as a phase reference.

Ideal for OEM machinery applications with easy integration.

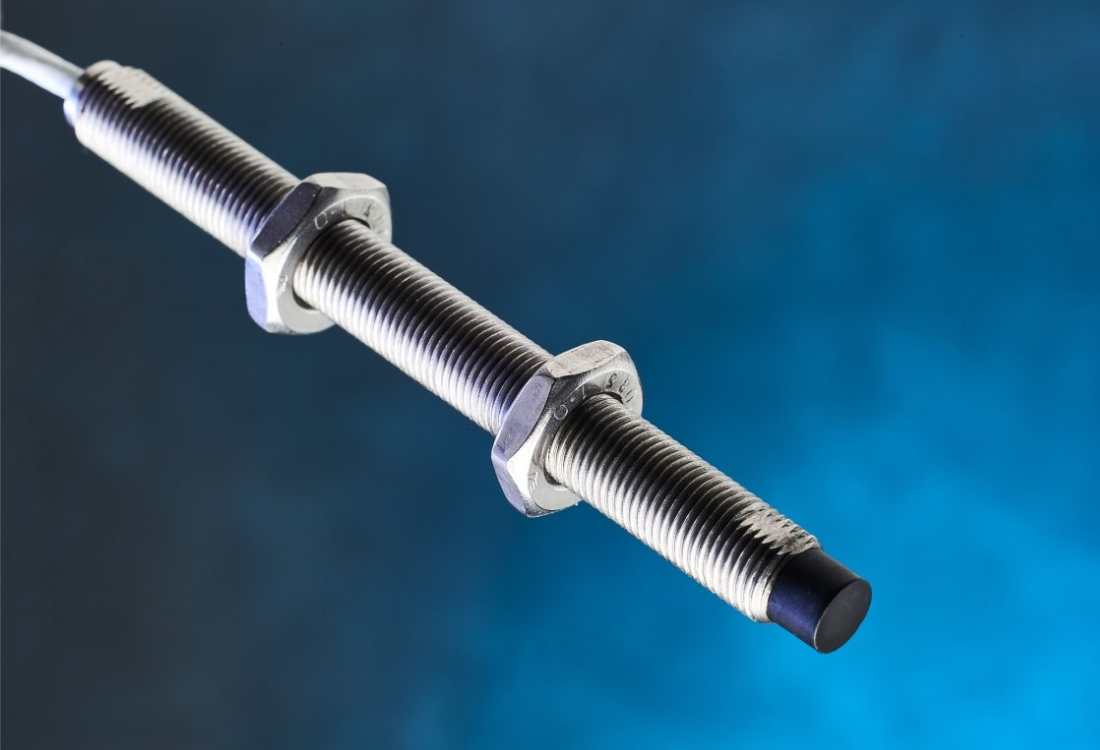

Senturion X Proximity Probe Systems (with direct processed outputs)

DNX8031, 4-20mA Loop-Powered, Vibration Transmitter, up to

0-250um pk-pk. Direct DCS/PLC integration for shaft vibration monitoring for fluid film bearings on motors, pumps, compressors and steam turbines.

DNX8033, 4-20mA Loop-Powered, Shaft Pos/Thrust Transmitter, -1.0mm to +1.0mm. Direct DCS/PLC integration for shaft position/thrust wear monitoring on a wide range of machinery,

e.g. pumps, compressors and steam turbines.

PZDC (Piezo) & VEL/GDC (Moving Coil) Velocity Vibration Transmitters (with direct processed outputs)

Distributed monitoring & protection, Ideal lower cost solution for medium to low criticality assets - Direct DCS/PLC/BMS/SCADA integration

PZDC A small 4-20mA Loop-Powered, Piezo Velocity Vibration Transmitter for absolute casing vibration, applications include motors, pumps, fans, centrifuges & vibrating screens, ranges from 0-15mm/sec RMS up to 0-100mm/sec RMS velocity vibration.

VEL/GDC A slightly larger 4-20mA Loop-Powered, Moving Coil Type Velocity Vibration Transmitter with additional dynamic signal output for absolute casing vibration, applications again are motors, pumps, fans compressors, engines and process equipment but with high noise immunity and excellent unwanted high frequency vibration rejection, ranges 0-15mm/sec RMS up to 0-50mm/sec RMS velocity vibration, or 0-100µm to 0-500µm displacement vibration.

Our Products

Download the engineers’ guide to specifying vibration monitoring systems

If you are designing a system which uses vibration monitoring then this guide can help you specify vibration monitoring systems.

This guide covers:

- Types of vibration sensors

- Monitoring equipment

- Questions to ask when designing or specifying a vibration monitoring system

- Why work with Sensonics

Please enter your details in the form to get your copy.

Get your copy

Our services

YOU MIGHT ALSO BE INTERESTED IN...

Turbine Supervisory Instrumentation

Industrial Sensors

Speed Monitoring Solutions

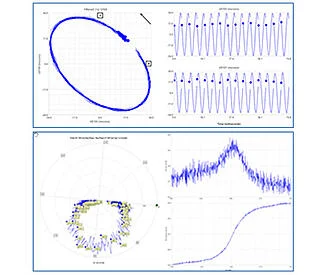

Condition Monitoring

Download Our Free Proximity Transducer Systems

The Senturion X proximity eddy current probe system has evolved from our established range, now offering a universal driver concept in addition to various other features.

Included In The Guide:

• Straight and reverse mount probes

• Extension cables and driver units

• Standard Senturion X features

• Other Sensonics products...

What's New

Latest news

Book A Consultation With Our Expert Jason