Understanding Capacitive Air Gap Sensors: Applications And Benefits In Hydrogenerators

In industrial applications that utilise hydrogenerators, it is essential to ensure the optimum performance and safety of processes and systems. Capacitive air gap sensors play a vital role in monitoring the air gap - the space between the rotor and stator - within a hydrogenerator, ensuring that potential technical problems are quickly identified and any inefficiencies are flagged for immediate resolution.

So, how do capacitive air gap sensors function and what are their applications and benefits in hydrogenerators?

How Do Capacitive Air Gap Sensors Work?

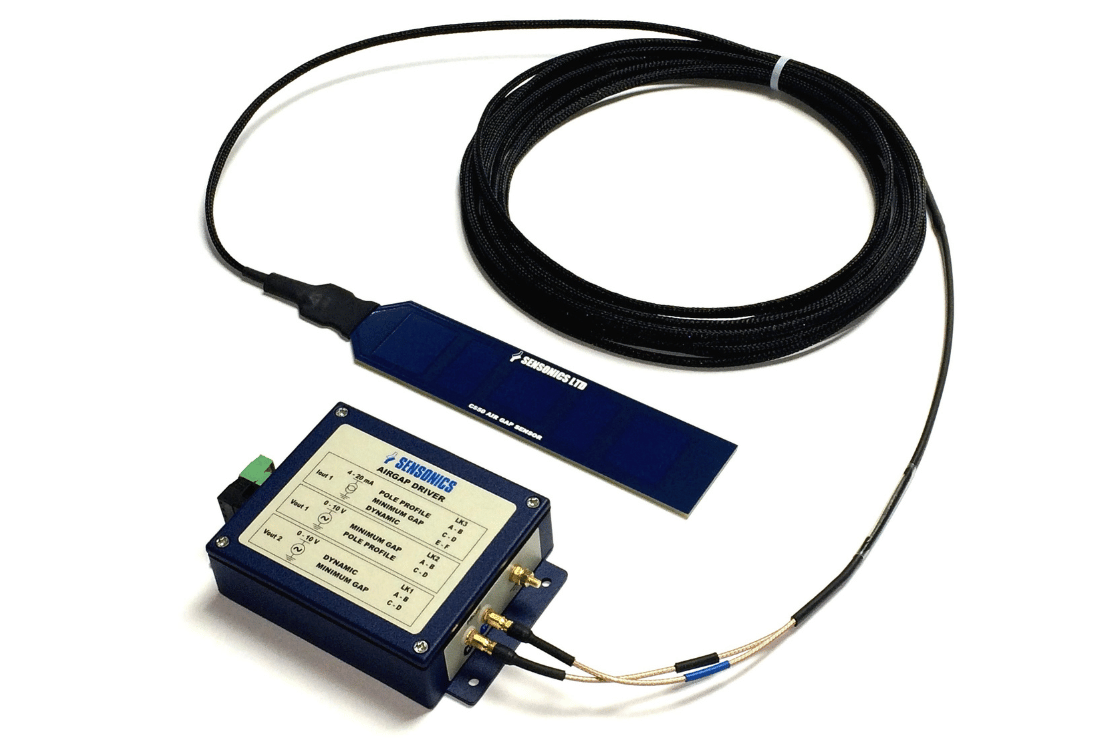

Capacitive air gap sensors are designed to measure the distance between the rotor and stator by utilising the principle of capacitance: the ability of a system to store an electrical charge. The sensor consists of two conductive plates, one fixed and one connected to the rotor or stator. When an electric field is applied, the distance between these plates affects the capacitance value.

As the rotor spins within the stator, the air gap can vary due to factors such as thermal expansion, mechanical wear, or misalignment. Capacitive sensors detect these variations by measuring changes in capacitance. When the gap widens or narrows, the capacitance value changes, providing real-time data on the air gap's condition. This information is critical to maintain the proper alignment and operation of the hydrogenerator.

Applications Of Capacitive Air Gap Sensors In Hydrogenerators

Capacitive air gap sensors are widely used in hydrogenerators to ensure optimum performance and to prevent potential issues. An important application is monitoring the uniformity of the air gap. A consistent air gap is essential for the efficient generation of electricity, as any variation can lead to uneven magnetic fields, resulting in vibration, noise, and reduced efficiency.

Additionally, these sensors are crucial to detect rotor-stator contact. If the air gap becomes too narrow, the rotor may come into contact with the stator, causing significant damage to both components. Capacitive sensors provide early warnings of such situations, allowing operators to take corrective actions before a catastrophic failure occurs.

What Are The Benefits Of Capacitive Air Gap Sensors?

The use of capacitive air gap sensors in hydrogenerators offers two key benefits:

Firstly, they provide accurate real-time monitoring of the air gap, enabling operators to maintain optimum operating conditions. This leads to improved efficiency, as the hydrogenerator can operate with minimal energy losses.

Secondly, by quickly detecting potential issues, capacitive sensors help to reduce the risk of costly repairs and unplanned downtime. By improving predictive maintenance, the sensors ensure that any necessary interventions are made before a minor problem escalates, thereby prolonging the lifespan of the hydrogenerator.

Contact Us To Find Out More

For more information about how Sensonics can help to improve the monitoring of your business’s hydrogenerators, please get in touch today.